WE OFFER HIGH-QUALITY ENGINEERING SERVICES AND CUTTING-EDGE PRODUCTS FOR PHYSICAL MODELING AND MOTION ANALYSIS OF HUMANS IN TRANSPORT SYSTEMS AND HEAVY MACHINERY

Services:

Measurement and analysis of human vibration

Development of solutions for the mitigation of human vibration

Development of whole-body inertial motion capture systems

Modeling of biomechanical systems

PRODUCTS AND TECHNOLOGIES

Seat Suspension System

Studies show that heavy-machinery and truck operators are at high risk of suffering back pain and other musculoskeletal injuries due to steady exposure to whole-body vibration.

In 2018, there were close to 5 million operators of heavy machinery, trucks and buses in the US alone. The estimated cost for back pain for each operator can exceed $2,000 per year, which can translate into tens of millions in healthcare costs to the heavy-machinery sector.

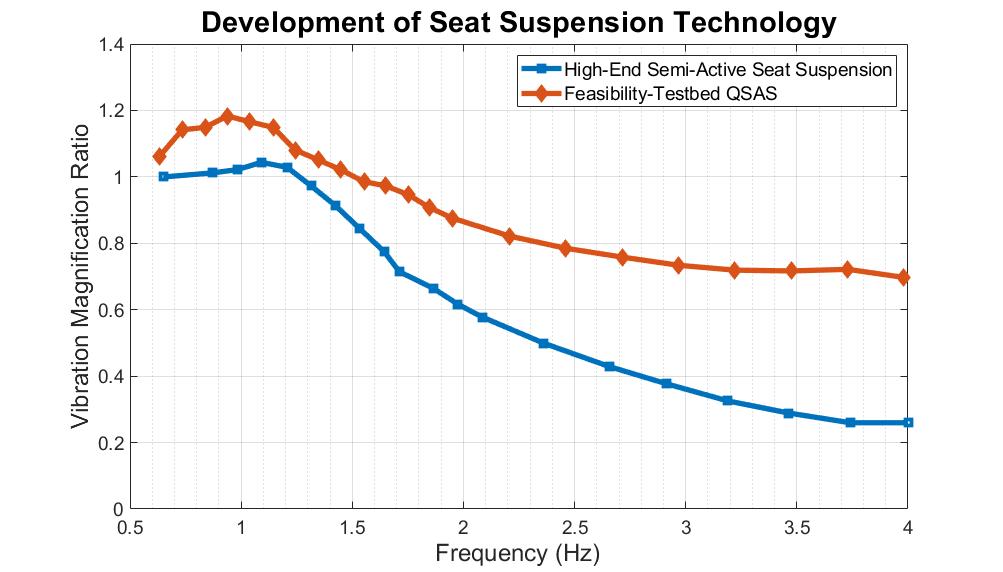

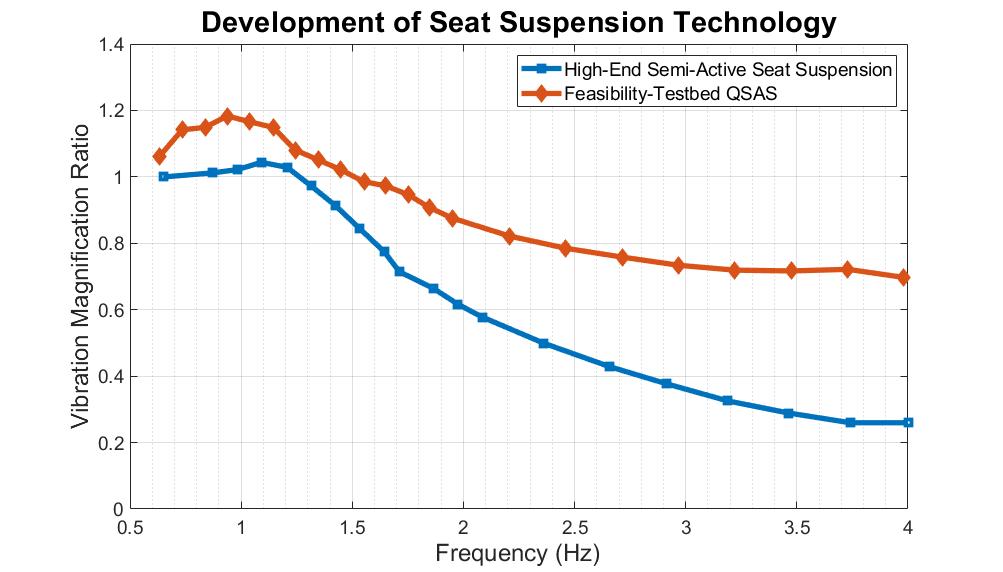

Most existing seats in heavy machinery are passive and are not effective in reducing vibration transmitted to the operator in the low frequency range.

The state-of-art seats with active and semi-active seats can provide more-effective vibration mitigation but are unaffordable for most users. Supported by the National Science Foundation, ActiBioMotion, LLC demonstrated the feasibility of a novel family of quasi-semi-active seat (QSAS) technologies that will significantly mitigate transmitted vibration in the low-frequency range—similar to semi-active seats but with a price similar to passive seats.

The steps to bring the QSAS from the feasibility stage to the commercial stage are currently underway.

Seat Suspension System

Studies show that heavy-machinery and truck operators are at high risk of suffering back pain and other musculoskeletal injuries due to steady exposure to whole-body vibration.

In 2018, there were close to 5 million operators of heavy machinery, trucks and buses in the US alone. The estimated cost for back pain for each operator can exceed $2,000 per year, which can translate into tens of millions in healthcare costs to the heavy-machinery sector.

Most existing seats in heavy machinery are passive and are not effective in reducing vibration transmitted to the operator in the low frequency range.

The state-of-art seats with active and semi-active seats can provide more-effective vibration mitigation but are unaffordable for most users. Supported by the National Science Foundation, ActiBioMotion, LLC demonstrated the feasibility of a novel family of quasi-semi-active seat (QSAS) technologies that will significantly mitigate transmitted vibration in the low-frequency range—similar to semi-active seats but with a price similar to passive seats.

The steps to bring the QSAS from the feasibility stage to the commercial stage are currently underway.

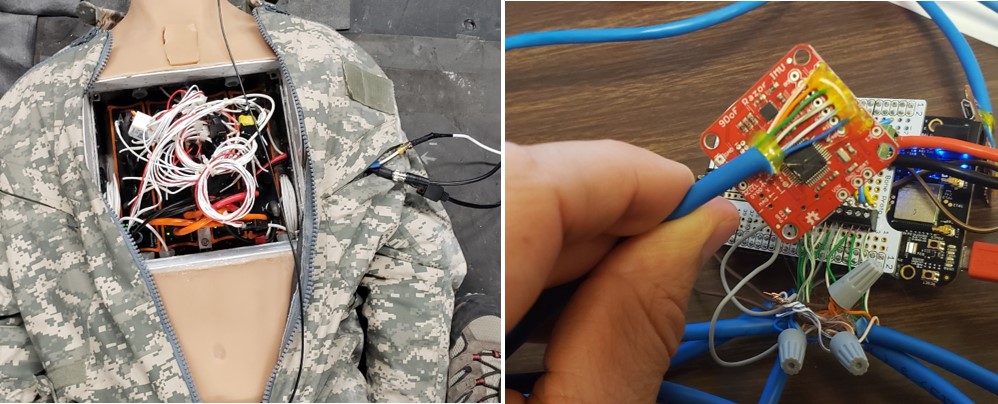

The Instrumented Supine Manikin for Vibration (ISMv)

The ISMv is designed to facilitate development, testing, evaluation, and down-selection of human transport systems. The ISMv exhibits a supine human-like biomechanical response when exposed to vibration. The ISMv is equipped with embedded sensors and data acquisition hardware that, when paired with our custom analysis software, provides a turn-key solution for recording and analyzing the effects of vibration on a supine human.

Features:

- Validity – The ISMv has been validated against human data for both shock and vibration testing

- Simplicity – The ISMv has only two external wires and the custom software fully processes the collected data, generating a wide range of useful metrics and plots.

- Repeatability – The ISMv’s vibration responses are robust and repeatable. The many variabilities and uncertainties associated with human testing do not impact the ISMv, resulting in an improved ability to isolate the parameters of interest

- Durability – Designed for military testing, the ISMv works in a wide range of temperatures and can endure violent shocks without damage

Potential Applications:

- Can replace human subjects during system design and evaluation

- Can be used in extreme settings that could be unsafe for humans

Custom Motion and Vibration Sensors

The quality of any analysis is heavily dependent on the quality of the data captured. This is especially true in motion capture due to the astounding complexity of the human body and its interaction with the surrounding equipment. Many motion capture systems exist, but after thorough testing, we concluded that such generic systems may not be well-suited to study motion caused by vibration. Therefore, we are currently developing sensors and sensing systems that are tailored to capturing human vibration as accurate as possible.

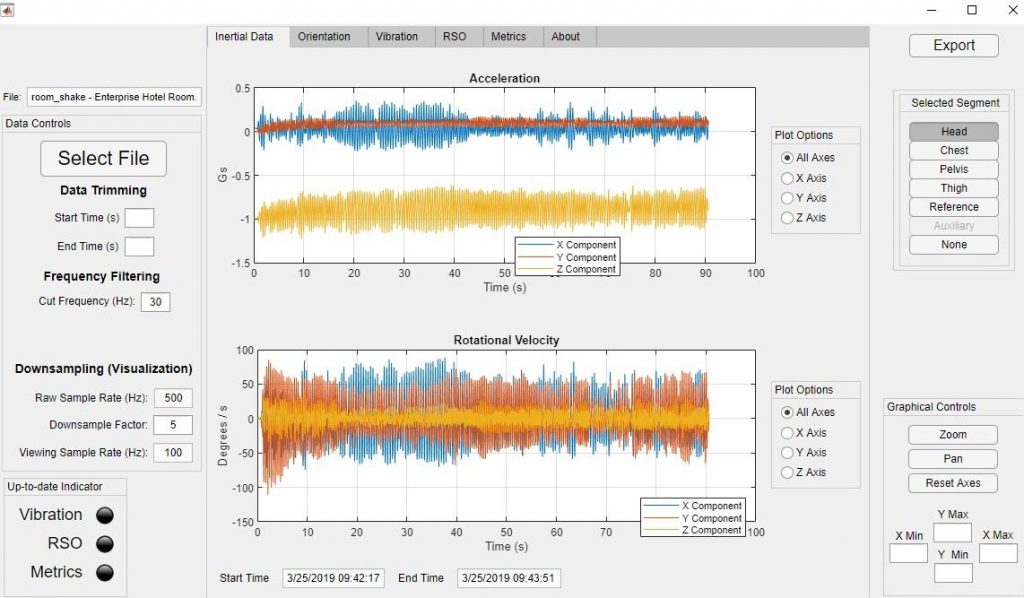

Vibration Analysis Software

ActiBioMotion has developed a library of software algorithms for monitoring and analyzing human motion and vibration. These algorithms can interpret the effects of shocks and vibration, as well as those of posture changes and limb flexion. The effects can be expressed via a variety concise metrics and easy-to-understand plots. Custom software packages can be constructed to cater to specific customer needs. Data can also be sent to ActiBioMotion for processing and calculation of customer-specific results.

EXPERTISE

At ActiBioMotion, we strive to achieve the most thorough and accurate analyses possible. To that end, we have expertise in all steps of the process of human vibration analysis, from study design and data collection to reporting results and providing recommendations.

Areas of Expertise include:

- Development of testing protocols for field and laboratory situations

- Capture of human motion

- Analysis and mitigation of human vibration in manned and unmanned transport systems

- Development of predictive models for supine human vibration in transport systems

- In-depth knowledge of MEMS sensors and data acquisition hardware and software

- Experience working with and providing services and solutions for the U.S. military

OUR CUSTOMERS & PARTNERS

ActiBioMotion has partnered with, sponsored by, and/or funded by the military, industry, educational, and business development entities.

- National Science Foundation (NSF)

- Iowa Innovation Corporation (IICorp)

- U.S. Army Medical Research and Development Command (USAMDRC)

- U.S. Army Aeromedical Research Laboratory (USAARL)

- U.S. Army Medical Materiel Development Activity (USAMMDA)

- UI Ventures

- Battelle

- Cornerstone Research Group (CRG)

ABOUT US

Khalid Barazanji, PhD Co-Founder / CEO

Dr. Khalid Barazanji is a Co-Founder/CEO with ActiBioMotion. Dr Barazanji is responsible for overseeing government R&D contracts and grants, and for monitoring process development and control for commercial implantation services. Dr. Barazanji was the formal Chief of Enroute Care and Airworthiness Division at the U.S. Army Aeromedical Research Laboratory (USAARL), Fort Rucker, Alabama. He has more than 19 years of experience working at USAARL in the area of medical transport research and testing. He has extensive expertise in the area of medical equipment airworthiness, human factors, and vibration research.

Salam Rahmatalla, PhD Co-Founder / CTO

Dr. Rahmatalla is a Co-Founder and Chief Technology Officer with ABM. Addtionally, Dr. Rahmatalla is a professor at the University of Iowa in structure mechanics and biomechanics. He has more than a decade of expertise in the areas of motion capture, motion analysis, and motion simulation. Dr. Rahmatalla has many publications in peer-review journals and has presented at many national and international conferences.

Contact Us